When it comes to ensuring the house’s integrity and saving the system from water pressure. Pressure vacuum BRekaer is the first choice homeowners go for. With all the fuzz around What Is A Pressure Vacuum Breaker? PVB is a device that helps to prevent the contamination of drinking water from water backflow. By using a check valve and air inlet valve this device prevents the water pressure from creating a water vacuum. Maintaining minimal water pressure ensures the safety of the water supply alongside your family.

In this blog, we will discuss in-depth information about A PVB device. We will also explain why this single device is important for your house and family health. As well as simple installation and maintenance steps for longer utilization.

What Is A Pressure Vacuum Breaker

A pressure vacuum breaker is a device used to prevent backflow in plumbing systems. It works by creating a barrier that prevents water from flowing back into the main water supply. These devices are commonly used in irrigation systems and outdoor plumbing fixtures to protect against contamination.

A pressure vacuum breaker is commonly known as a vacuum breaker. It is a crucial component in plumbing systems that helps prevent backflow in water systems. Backflow occurs when the flow of water turns backward. Making contaminated water enter the clean water supply. This can lead to health hazards and contamination of the water supply.

How Does A Pressure Vacuum Breaker Work?

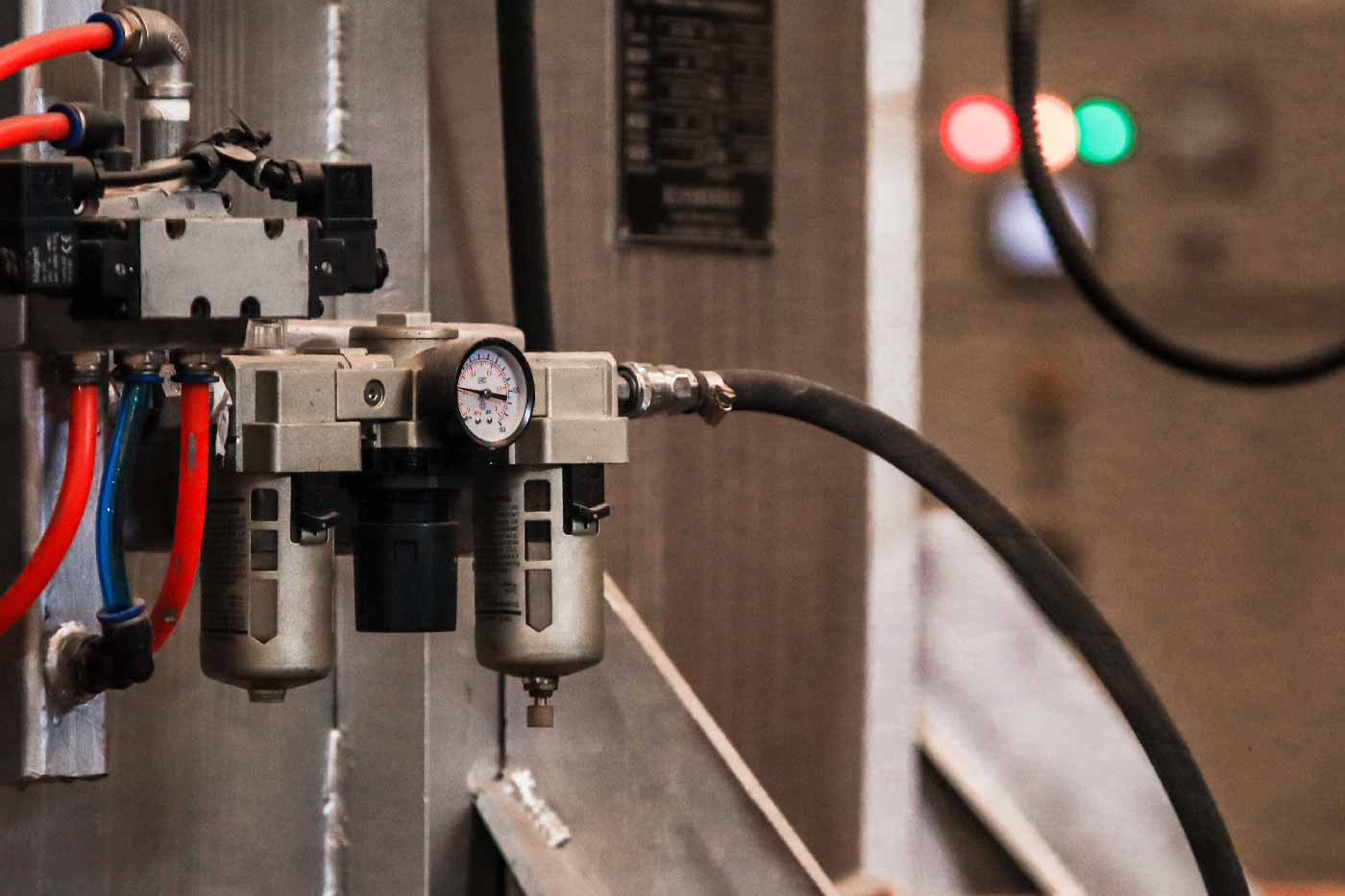

A pressure vacuum breaker operation is quiet and effective as well. It consists of two main parts: a check valve and an air inlet valve. The check valve permits water to flow in one direction while preventing it from flowing backward. The air inlet valve allows air to enter the system, creating a pressure vacuum. This vacuum helps to break the flow and prevents backflow.

When there is an increase in pressure within the plumbing system. Like pressure failure in the system or pump. The check valve closes, preventing water from flowing backward. Necessarily, the air inlet valve opens, allowing air to enter and create a backward pressure. This breaks the vacuum and stops the water from flowing in reverse. Which is why it’s so effective in preventing backflow.

The Importance Of Backflow Prevention

Protecting the Clean Water Supply

A pressure vacuum breaker plays a vital role in safeguarding the integrity of the water supply. Preventing the backward flow of contaminated water ensures that only clean, potable water reaches our taps, reducing the risk of waterborne diseases and health hazards.

Adherence to regulations

Plumbing codes requires the installation of pressure vacuum breakers. In order to comply with backflow prevention regulations and better agreements. By implementing this device, property owners and plumbers stay in compliance with local laws and regulations. While also avoiding potential fines and penalties.

Maintaining water quality

Backflow incidents can contaminate the stream water supply. Things like hazardous substances, chemicals, and bacteria can contaminate them. Pressure vacuum breakers act as a critical barrier. They prevent this contamination and maintain a high quality of our drinking water.

Preventing cross-connections

Cross-connections between potable and non-potable water sources can occur. In settings, like residential, commercial, and industrial spaces this is fairly common. Pressure vacuum breakers effectively prevent cross-connections. Eliminating the risk of cross-contamination and protecting the integrity of the clean water supply.

Cost-effective solution

Installing a pressure vacuum breaker is a cost-effective measurement. In comparison to other potential consequences of backflow incidents. By integrating this device into the plumbing system. Both homeowners and businesses can safeguard their health and investments.

As an essential component of any plumbing system, a pressure vacuum breaker ensures the safety and quality of our drinking water. By understanding how it works and acknowledging the importance of backflow prevention, we can take proactive measures to protect ourselves, our communities, and the environment from the dangers of contaminated water.

Common Applications For Pressure Vacuum Breakers

Residential Irrigation Systems

A pressure vacuum breaker (PVB) is commonly used in residential irrigation systems to protect against backflow contamination. To stop water from returning to the main water supply, a PVB is installed at the sprinkler system’s water outlet. This guarantees that the water utilized for the water system stays separate from the public water supply, defending against expected contaminations and synthetics that might be available in the water system framework.

Commercial Watering Systems

Pressure vacuum breakers are common in commercial settings. Places such as parks, sports fields, and golf courses, to maintain the water supply’s safety and integrity. These frameworks help to prevent water system reversal. This can happen anytime if there is a sudden drop in pressure in the water system. By creating a vacuum it prevents foul water from entering into the normal water supply.

Installation And Maintenance Of Pressure Vacuum Breakers

Pressure vacuum breakers are essential for the installation and maintenance of plumbing systems as they prevent the backflow of contaminants into the water supply. These devices create a vacuum to break the pressure and protect water quality.

Installing and maintaining a pressure vacuum breaker (PVB) is crucial for the proper functioning of your plumbing system. Understanding the proper installation guidelines and maintenance checklist can ensure the longevity and effectiveness of your PVB.

Proper Installation Guidelines

When it comes to installing a pressure vacuum breaker, it is essential to follow these guidelines to guarantee its correct operation:

Locate the ideal placement

Select an area with better ventilation. Position the PVB at least 12 inches above the highest point in your irrigation system. This elevation will ensure maximum performance for your system.

Protect from freezing

Install the PVB in an area that can protect your device from a freezing atmosphere. Proper insulation or heat tape can help when you are dealing with cold situations. In this way, you can also prevent damage by freezing conditions.

Consider local regulations

Familiarize yourself with the specific plumbing codes and regulations in your area. This ensures compliance and helps avoid potential issues down the line.

Secure connections

Use appropriate fittings to ensure leak-free connections. Tighten the nuts and bolts properly without overtightening, as this may lead to damage or leaks.

Keep it accessible

Make sure the PVB is easily accessible for future inspections, repairs, and maintenance. This accessibility will save you time and effort in the long run.

Maintenance Checklist Tips For Longevity

To ensure the longevity and functionality of your pressure vacuum breaker, it is necessary to conduct regular maintenance using the following checklist:

- Visual inspection: Regularly examine the PVB for signs of wear, leaks, or damage. Look for cracks, corrosion, or loose fittings, and address any issues immediately.

- Clean the vents: Inspect the air vents to ensure they are clear of debris or obstructions. Clear any blockages, using a brush or high compression of air blast.

- Check valve operation: Verify that the check valves are working correctly. They should open and close smoothly without any resistance. Replace any faulty valves promptly.

- Test the backflow preventer: Periodically test the backflow preventer to confirm its effectiveness. This can be done using a gauge or a professional testing kit. Consult the manufacturer’s instructions for the appropriate testing protocol.

- Flush the system: Regularly flush your irrigation system to remove any materials or debris that may accumulate over time. This preventive measure helps maintain optimal performance.

Remember, proper installation and ongoing maintenance are crucial for the efficient operation of your pressure vacuum breaker. Following certain guidelines and regular check-ups will ensure optimal conditions. By which you can ensure the safety of your drinking water and extend the life of your PVB.

Choosing The Right Pressure Vacuum Breaker For Your Needs

Now that you know What Is A Pressure Vacuum Breaker it’s time to pick the right PVB. For safety and reliability reasons a pressure vacuum breaker (PVB) plays a crucial role. But with so many options choosing the right PVB for your needs can be hard to figure out. It’s important to consider several factors, top brands in the market, and why houses require a PVB.

Factors To Consider

Before making a decision, it’s essential to keep a few key factors in mind:

- Water Pressure: Determine the water pressure in your area, as different pressure vacuum breakers are suitable for different water pressure levels.

- Application: Consider the proper use of the pressure vacuum breaker. Are you installing it for a residential property, commercial building, or irrigation system?

- Size and Space: Ensure that you choose a pressure vacuum breaker. If it fits the available space and meets the size requirements of your plumbing system.

- Price Range: Set a budget and explore options within that range. Keep in mind that quality and reliability should be the primary consideration. So while making a decision don’t look over price alone.

- Manufacturer Warranty: Check if the pressure vacuum breaker accompanies a manufacturer guarantee. In the event of any defects or malfunctions, this may offer assurance and protection.

Top Brands In The Market

Several reputable brands offer high-quality pressure vacuum breakers. The following are some of the top brands worth considering:

| Brand | Features |

| Apollo Valves | Known for their durable construction and reliable performance, Apollo Valves pressure vacuum breakers are a popular choice among professionals. |

| Watts | With their extensive experience in the industry, Watts offers a range of pressure vacuum breakers with advanced features to ensure optimal protection against backflow. |

| Febco | Febco pressure vacuum breakers are known for their easy installation and maintenance, making them a preferred choice for homeowners and DIY enthusiasts. |

| Wilkins | Wilkins’s pressure vacuum breakers are designed to meet stringent industry standards, providing reliable backflow prevention for residential and commercial applications. |

Why Houses Require A PVB

By installing a PVB, you ensure that the water always flows in the right direction. Protecting your drinking water from potential pollutants and also your system from blocking up. This is especially important for houses with irrigation systems or other sources. Mostly for systems that could introduce non-potable water into the plumbing system.

Choose a pressure vacuum breaker that meets your specific needs. Make sure it provides reliable protection against backflow, ensuring the safety of your water supply. Don’t jump for any PVB when you’re facing a problem. Be more creative and accurate about it when it comes time to choose one.

Troubleshooting And Repairing Pressure Vacuum Breakers

A pressure vacuum breaker is a critical component of your irrigation system. They ensure the safety of your potable water supply. However, like any device, it can have issues that may require troubleshooting and repair. So it’s common to have ideas about the repair and maintenance of pressure vacuum breakers. This will enable optimal performance and better health integrity along with your house.

Identifying Common Issues

When it comes to identifying common issues there are a few key choices. Such as leaks, abnormal pressure with water flow, or an irregular discharge from the device. Additionally, visible signs of corrosion or damage to the components can be your root cause.

Steps To Fixing A Faulty Pressure Vacuum Breaker

It is essential to address any abnormalities with your pressure vacuum breaker. When attempting to fix or troubleshoot a broken pressure vacuum breaker, follow these steps:

- Inspect the device for any visible damage, leaks, or corrosion, focusing on the valve components and seals.

- Clean the pressure vacuum breaker to remove any debris or sediment that may be obstructing the proper flow of water.

- Test the device for proper functionality by conducting a system check. This will make sure that all components are operating as they are meant to.

- If necessary, replace any faulty or worn-out parts. This will restore the pressure vacuum breaker to its previous optimal working conditions.

Frequently Asked Questions

What Is A Pressure Vacuum Breaker?

A Pressure Vacuum Breaker (PVB) is a mechanical device used in plumbing systems to prevent the backflow of contaminated water into the main water supply.

How Does A Pressure Vacuum Breaker Work?

A Pressure Vacuum Breaker works by utilizing a check valve and an air inlet valve. It creates a barrier that keeps foul water from streaming into the main water stream. The air inlet valve opens when the water pressure drops. This allows the air to enter the system and prevents backflow.

Why Is A Pressure Vacuum Breaker Important?

A Pressure Vacuum Breaker is essential. Because it guarantees that the water in your pipe framework stays safe and contamination-free. It keeps you and your family safe through the prevention of harmful substances.

Conclusion

To safeguard drinking water supplies from contamination, a pressure vacuum breaker is an essential component. Understanding its capability and support is fundamental for guaranteeing the security and honesty of our water frameworks. We can maintain the health and well-being of our communities by adhering to the appropriate installation and maintenance guidelines.