Pipe plugs are one of the essential tools in a plumber’s toolbox. They serve as temporary seals in pipes and fittings to prevent leaks or block the flow of water, gas, or other fluids. If you’re a plumber, it’s essential to know how to use pipe plugs properly to ensure their efficacy and efficiency. In this article, we’ll discuss some pipe plug best practices that plumbers need to know.

Choose the right size and type of pipe plug

The first thing to consider when using a pipe plug is choosing the right size and type for the job. Pipe plugs come in different sizes, materials, and designs to suit different pipe sizes, fluids, and pressures. Using the wrong size or type of pipe plug can result in leaks or damage to the pipe.

When selecting a pipe plug, make sure it fits snugly into the pipe or fitting without overstretching or deforming the plug. Also, consider the material of the plug, especially if you’re dealing with corrosive or high-temperature fluids. For instance, a rubber plug may not withstand the heat or chemicals present in a gas line, while a metal plug may cause galvanic corrosion when used in a copper pipe.

Prepare the pipe or fitting before using the plug

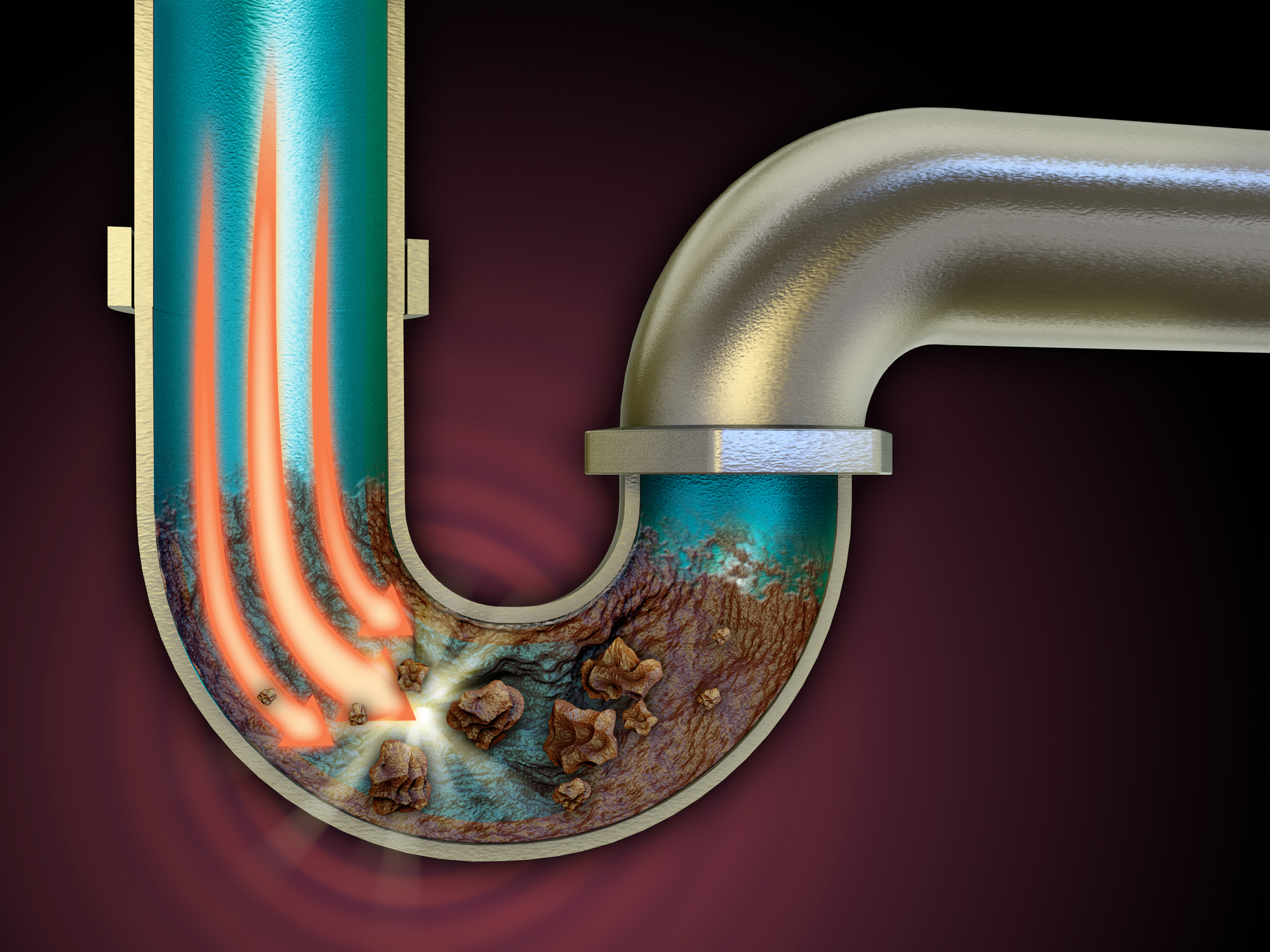

Now that you’ve chosen the right pipe plug, it’s time to prepare the pipe or fitting before inserting the plug. This step involves cleaning and drying the pipe and removing any debris or obstacles that may interfere with the plug’s sealing ability.

For example, if you’re plugging a drain line, you may need to use a drain snake to remove any clogs or buildup before inserting the plug. If you’re working on a threaded fitting, you may need to run a tap or die to clean and restore the threads’ integrity.

Install the plug according to the manufacturer’s instructions

Once you’ve prepared the pipe or fitting, it’s time to install the pipe plug according to the manufacturer’s instructions. Pipe plugs come in different designs, including mechanical, inflatable, and expandable, and require different installation procedures.

For instance, a mechanical pipe plug may require tightening a central bolt to expand the plug’s wings and create a seal around the pipe. An inflatable plug may require inflating the plug using air or water pressure to fill the space against the pipe walls and create a tight seal. An expandable plug may require inserting the plug into a special tool and expanding it to fit the pipe’s bore.

Regardless of the type of pipe plug, make sure you follow the manufacturer’s instructions carefully to avoid damaging the plug or the pipe and ensure proper sealing.

Test the plug for leaks and stability

After installing the pipe plug, you need to test it for leaks and stability before leaving the job site. Testing involves applying pressure to the pipe system, either with air or water, and checking for any signs of leakage or movement.

If the plug fails the test, you may need to tighten it, inflate it more, or replace it altogether with a better fit or type. Avoid leaving a job site without ensuring that the pipe plug is working correctly, as this can lead to costly repairs and potential hazards.

Dispose of the plug responsibly

Finally, after completing the job, you need to dispose of the pipe plug responsibly. Pipe plugs, like any plumbing product, can pose environmental and safety risks if not disposed of properly.

Check your local regulations regarding the disposal of plumbing products and follow them accordingly. For instance, some plugs may need to be recycled, while others may require special handling to prevent pollution.

Conclusion

Pipe plugs are valuable tools for plumbers to temporarily stop flows or prevent leaks, but they require proper installation and care to achieve their full benefits. When using a pipe plug, choose the correct size and type for the job, prepare the pipe or fitting, install it according to the manufacturer’s instructions, test it for leaks and stability, and dispose of it responsibly. By following these pipe plug best practices, plumbers can ensure their clients’ safety and satisfaction. If you’re looking for reliable and professional plumbing services, visit aceplumbingrepair.com or call us at (844) 711-1590.