Perfectly structural homes frequently accompany cast iron channel pipes that, over the long run, may require substitution because of wear and consumption. Moving up to current materials like Acrylonitrile Butadiene Styrene (ABS) can further develop strength and simplicity of establishment. In this thorough aide, we’ll take you through a journey on how to replace cast iron drain pipe with ABS, guaranteeing smooth progress and a more productive pipe framework.

What is ABS PIPELINE?

Acrylonitrile Butadiene Styrene, generally known as ABS. This is a sort of thermoplastic polymer that generally utilizes in the assembling of lines and fittings for different pipe applications.

Materials of ABS pipe

ABS is made out of three principal monomers: acrylonitrile, butadiene, and styrene. This blend results in a tough and intensity-safe thermoplastic with brilliant mechanical properties.

Famous Highlights

Sturdiness: ABS pipes are known for their sturdiness, giving a dependable answer for plumbing frameworks. They are impervious to effect and scrap spots, making them appropriate for both underground and more ground establishments.

Temperature Resistance

ABS lines can endure a wide temperature range, making them reasonable for both hot and cold water applications. They are especially successful in channel, waste, and vent (DWV) frameworks.

Chemical Resistance & Light Weight

ABS pipes display protection from different synthetic compounds normally tracks down in family and modern conditions. Likewise, ABS is lightweight when we compare with some other channeling materials, which works with simpler taking care of and establishment. Which helps in setting aside cost cash.

Ease of Installation

ABS pipes are known for their simplicity of establishment. They can be utilizable dissolvable concrete, which makes major areas of strength for a dependable connection among lines and fittings.

Simple Guide on How to Replace Cast Iron Drain Pipe with Abs

Preparation

- Focus on well-being by wearing defensive stuff, including gloves and security glasses.

- Switch off the water supply to the impacting pipes region.

- Distinguish and find the wipe-out passage to ease tension in the pipes framework.

Evaluation and Arranging:

Lead a careful evaluation of the cast iron line’s condition, examining for any indications of erosion or harm. With the assessment complete, fastidiously plan the substitution course for the ABS pipe, considering the vital incline to guarantee legitimate waste. This essential arranging establishes the groundwork for an effective and productive substitution process.

Measure and Cut ABS Line:

Given a reasonable arrangement, measure the correct length for the substitution ABS pipe. Outfitting with these estimations, use a responding saw or saw to definitively slice the ABS line to the correct length. The exactness of this step is indispensable for accomplishing a consistent and secure fit during establishment.

Eliminate Cast Iron Line:

Progressing to the expulsion stage, utilize a responding saw to cut the cast iron line at the two finishes. Practice wariness to forestall harm to encompassing lines, guaranteeing a spotless and controllable expulsion process. By executing this step tirelessly, you are ready for the incorporation of the new ABS pipe flawlessly.

Clean the Center point:

Set up the center point, or fitting, where the ABS line will cozily fit by carefully cleaning it with a wire brush. A debris-free and smooth surface is vital for laying out a safe and leak-free association between the ABS pipe and the current pipe framework.

Attach Rubber Coupling:

Slide an elastic coupling onto the finish of both the cast iron and ABS pipes. This critical part guarantees a watertight seal between the lines. The legitimate situation of the elastic coupling makes way for a solid association, limiting the gamble of breaks over the long haul.

Insert ABS Pipe:

Tenderly supplement the ABS pipe into the center point, directing it until it arrives at the midpoint of the elastic coupling. The cautious execution of this step is essential in accomplishing an exact fit, making way for the resulting fixing process.

Secure Rubber Coupling:

When the ABS pipe is ready, fix the braces on the elastic coupling utilizing a screwdriver or wrench. This activity guarantees a cozy and secure fit, limiting the potential for spills. The hearty association laid out during this step is vital for the drawn-out usefulness of the pipes framework.

Test for Leaks:

With the ABS pipe safely set up, turn on the water supply and direct a careful check for any indications of holes around the association focuses. Expeditiously address any distinguishable holes by changing the clasps or making important adjustments, ensuring a watertight seal.

Support the ABS Pipe:

Use pipe holders decisively to help the ABS pipe, getting it set up along its course. Guarantee the appropriate slant is kept up with, working with powerful seepage and forestalling likely issues from now on. This step is vital in keeping up with the drawn-out dependability and usefulness of the substitution pipe.

Finalization Steps of How to Replace Cast Iron Drain Pipe with Abs

- Secure Licenses: Secure the vital licenses before starting the substitution.

- Proficient Help: For complex establishments or then again assuming you’re uncertain about any step, look for proficient pipes help.

- Discard Old Line: Appropriately discard the old cast iron line as you need by nearby guidelines.

- Inspection: Lead an exhaustive review of the whole substitution to guarantee a solid and release-free association.

- Clean-Up: Clean the workspace and discard any flotsam and jetsam dependably.

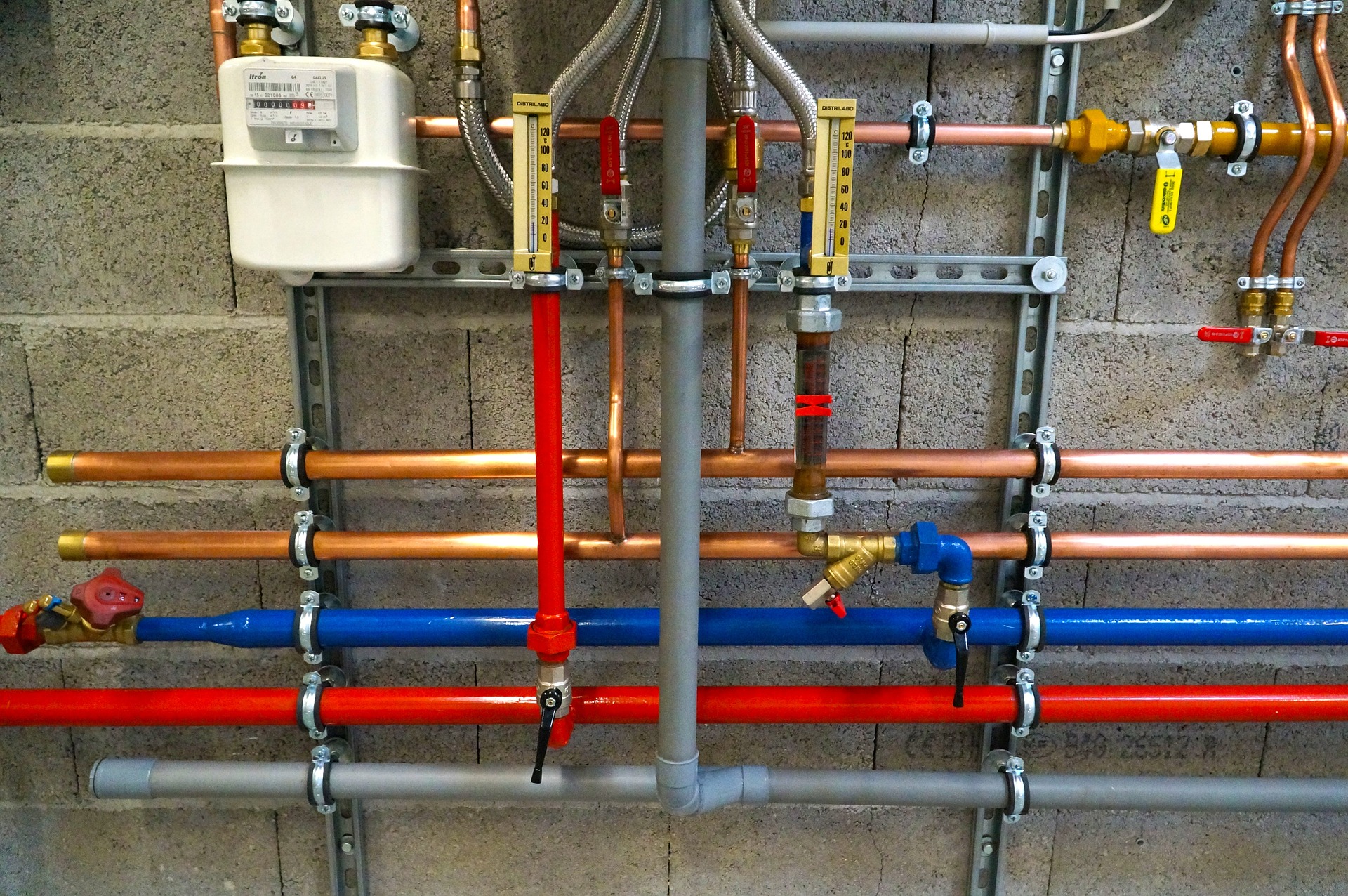

Iron Pipe or ABS

With the aid of the most proficient method to just supplant ABS pipe in your cast iron channel pipe framework, there remains an inquiry about which one is better: Iron channel line or ABS? Indeed, this isn’t difficult to reply to. The two components have their advantages and disadvantages. In this way, we want to sort out which one merits your cash and life span.

Pros and Cons of Iron Drain Pipe vs ABS Pipe

Durability

- Iron Lines: Known for solidness, particularly bendable iron, enduring high-pressure conditions.

- ABS Lines: Likewise sturdy, impervious to erosion, giving an enduring pipe arrangement.

Temperature Resistance

- Iron Lines: High-temperature opposition, reasonable for conveying heating water and steam.

- ABS Lines: Expansive temperature range however may not be great for incredibly high-temperature applications.

Weight and Establishment

- Iron Lines: Weighty, making transportation and establishment work accurate.

- ABS Lines: Lightweight, simple to deal with, and introduce, adding to general work and establishment cost reserve funds.

Cost

- Iron Lines: Higher forthright expenses because of material and establishment costs.

- ABS Lines: By and large more savvy as far as material and work costs.

Corrosion Resistance

- Iron Lines: Project iron lines are powerless to consumption, particularly in forceful conditions.

- ABS Lines: Consumption safe, giving a solid and enduring answer for plumbing applications.

Chemical Resistance

- Iron Lines: Restricted compound opposition contrasted with ABS pipes.

- ABS Lines: Show protection from different family and modern synthetic compounds.

Ultimately, there is no good answer to the question of which one is better. One offers you high strength with high temperatures or fire resistance but corrosion problems over time. So, ABS pipes are your better solution if you want cost-effectiveness, corrosion resistance, and ease of installation. However, consulting with an expert is available decision Ace plumbing Repair .

Conclusion

In conclusion, the matter of how to replace a cast iron drain pipe with ABS involves careful planning, precise execution, and adherence to safety and plumbing regulations. Also, the process of how to replace cast iron drain pipes with ABS is kind of a big challenge for professionals as well. From start to finish the whole process is a great journey that becomes successful when the work is a success.