by avi | Feb 17, 2024 | plumbing Services

Do you have thoughts on how vacuum breakers work? Well to figure that out first it’s important to have knowledge about what Vacuum breakers is. Vacuum breakers work by preventing backflow in plumbing systems. Allowing air to enter the pipes to equalize pressure and prevent siphoning. Now, let’s delve into the intriguing mechanics behind these devices.

Plumbing systems often face the risk of backflow, where water or other fluids flow in the opposite direction due to negative pressure or sudden drops. This can contaminate the potable water supply. Vacuum breakers, also known as backflow preventers, serve as safety valves to mitigate this risk.

What Is A Vacuum Breaker?

A vacuum breaker is a device that prevents backflow in plumbing systems. By creating a barrier to prevent siphoning. Vacuum breakers maintain water supply purity and protect against contamination. This is achieved through the creation of an air gap to interrupt the flow, safeguarding against potential hazards and ensuring the integrity of the water supply.

Understanding Vacuum Breakers

To understand how vacuum breakers work, it’s important to first understand what exactly a vacuum breaker is. A vacuum breaker is a device that plumbing systems use to prevent the backflow of water into the potable water supply. It’s essentially a valve that allows air to enter when there is a negative pressure or vacuum present.

When it comes to protecting our drinking water from contamination, vacuum breakers play a crucial role. Without a vacuum breaker, water can potentially flow back into the drinking water supply. If there is a pressure drop. This backflow can introduce harmful substances, bacteria, or even chemicals. Which can flow into the water supply, posing serious health risks and major water contamination.

Types Of Vacuum Breakers

Several types of vacuum breakers are commonly used in different plumbing systems. These include:

Pressure Vacuum Breaker (PVB)

You can typically find this on outdoor irrigation systems to prevent backflow. Places like garden hoses, sprinkler systems, or other non-potable water sources. It utilizes a spring check valve and an air inlet valve. Which helps to maintain the integrity of the potable water supply.

Atmospheric Vacuum Breaker (AVB)

An atmospheric vacuum breaker is common for indoor plumbing systems. Such as faucets, bathtubs, or toilets. It works by allowing air to enter the plumbing system whenever there is a negative pressure. Ultimately preventing any backflow.

Double Check Valve (DC)

This type of vacuum breaker consists of two spring-loaded check valves that lie in one line. Ensuring that water can only flow in one direction. It is common for high-risk applications. Such as industrial processes, where an additional level of protection is necessary.

By understanding the different types of vacuum breakers, you can choose the appropriate one for your specific plumbing system to ensure the safety and integrity of your drinking water supply.

How Vacuum Breakers Work

Understanding how vacuum breakers work is crucial. To prevent contamination or damage to plumbing systems. In this article, we will delve into the components of vacuum breakers, as well as the process through which they operate.

Vacuum Breaker Components

Vacuum breakers consist of several essential components. They tend to work together to protect plumbing systems from potential hazards. These components include:

| Component |

Description |

| Vacuum Chamber |

A sealed container is responsible for maintaining the necessary pressure within the plumbing system. |

| Check Valve |

A valve that allows the flow of fluid in one direction and prevents backward flow to avoid contamination. |

| Air Inlet |

An opening that allows air to enter the vacuum chamber and break the vacuum when necessary. |

| Float Assembly |

A mechanism that adjusts the position of the air inlet in response to changes in pressure within the plumbing system. |

The Vacuum Breaker Process

The vacuum breaker process involves a series of actions that allow air to enter the plumbing system, preventing the formation of a vacuum. This process can be summarized in the following steps:

Normal Operation

During normal operation, water flows through the plumbing system. While the check valve remains off to prevent any backflow.

Increase in Pressure

If there is an increase in pressure in the plumbing system. It causes factors such as thermal expansion or sudden water flow stoppage. The check valve remains off while the vacuum chamber fills with water.

Air Inlet Activation

As the water level rises within the vacuum chamber, it eventually reaches the float assembly. This triggers the float assembly to adjust the position of the air inlet. Allowing air to enter the chamber.

Air Relief

With the air inlet open, air enters the chamber and breaks the vacuum. Relieving the excess pressure within the plumbing system. This prevents damage or contamination.

Check Valve Closure

Once the excess pressure is out, the water level in the chamber decreases. Causing the float assembly to return the air inlet to its original position. The check valve can now close, ensuring the prevention of backflow.

Benefits Of Vacuum Breakers

Understanding the benefits of vacuum breakers is essential to maintain a safe and efficient plumbing system. These devices play a crucial role in preventing contamination and protecting equipment. By comprehending the advantages they offer, it becomes evident why vacuum breakers are necessary.

Preventing Contamination

Vacuum breakers are crucial in maintaining a hygienic and safe water supply system. They prevent contamination by ensuring that water flows in only one direction. Backflow, if left undone, can allow contaminants to enter the water supply. Posing serious health risks. Vacuum breakers act as the first line of defense, safeguarding the purity of potable water.

Protecting Equipment

One of the primary benefits of vacuum breakers is their ability to protect equipment from damage. By preventing backflow, these devices safeguard the integrity of plumbing systems. Such as irrigation lines and chemical dispensers. This means that valuable equipment is safe from potential contamination and damage. Thus ensures long-term operational efficiency.

Applications Of Vacuum Breakers

Plumbing System

Usually helps to prevent backflow and safeguard public health. Typically found on fixtures where water supply lines submerged. Such as faucets, toilets, and sprinkler systems.

By incorporating a check valve and an air inlet valve. Vacuum breakers create a barrier that prevents the reverse flow of water. When it comes to plumbing systems, vacuum breakers are integral components for various reasons. Such as protecting against chemical contamination, and maintaining water quality. Also complying with building codes and regulations.

They help prevent the waste of potable water by ensuring it remains separate from non-potable sources. Following plumbing regulations, it is important to install vacuum breakers at appropriate locations. Failure to do so may compromise the integrity of the plumbing system and pose health risks.

Industrial purposes

Vacuum breakers serve as a vital safety measure in many industrial applications. Especially where the risk of contamination or damage exists. Industries such as chemical production, food processing, and pharmaceutical manufacturing heavily rely on vacuum breakers. To protect their processes and products.

In industrial settings, vacuum breakers often combine with piping systems to prevent backflow during operation. This helps maintain the purity of substances when transferring. While also safeguarding equipment from damage by backpressure.

Furthermore, vacuum breakers ensure safer and more efficient operation of steam systems. They prevent the formation of vacuum conditions that can potentially lead to implosion. As well as the backflow of air or contaminants that can compromise the quality of the steam. By installing vacuum breakers in key areas of industrial processes. Businesses can minimize the risk of product contamination, and productivity with industry regulations.

Choosing The Right Vacuum Breaker

To ensure the proper functioning of your plumbing system and prevent the backflow. It is crucial to choose the right vacuum breaker. There are several factors to consider when selecting a vacuum breaker. Let’s explore those considerations in detail.

Considerations For Selection

When selecting a vacuum breaker, it is essential to keep in mind the following considerations:

- Application: Identify the specific application for which you require a vacuum breaker. This could be for a residential, commercial, or industrial plumbing system. The type of application will dictate the specific requirements your vacuum breaker needs to fulfill.

- Pressure Rating: Determine the maximum pressure that your plumbing system will experience. It is crucial to select a vacuum breaker that can handle the pressure without compromising its performance.

- Size: Consider the size of the vacuum breaker in light of the line or valve it will be introduced on. Guarantee that the components of the vacuum breaker match the prerequisites of your pipes framework.

- Compliance: Check if the vacuum breaker meets the necessary compliance standards and codes. This ensures that your plumbing system remains safe and up to code.

- Quality: Look for vacuum breakers from reputable brands known for their quality and reliability. Investing in a high-quality vacuum breaker will provide long-term effectiveness. As well as minimize the risk of potential issues.

Popular Vacuum Breaker Brands

When it comes to choosing a vacuum breaker, several brands have gained popularity due to their reliable performance and durability. Consider these reputable brands:

| Brand |

Description |

| Watts |

Watts vacuum breakers are known for their excellent craftsmanship and performance. They offer a wide range of vacuum breakers suitable for various applications and pressure requirements. |

| Woodford |

Woodford vacuum breakers are recommended for their quality and reliability. They offer vacuum breakers with different pressure ratings, ensuring compatibility with different plumbing systems. |

| Zurn |

Zurn vacuum breakers are famous among many professionals. Because of their superior performance and durability. Zurn offers vacuum breakers to meet the demands of modern plumbing systems. |

By considering these factors and exploring reputable brands. You can choose the right vacuum breaker that will effectively protect your plumbing system against backflow. Ensure your water system integrity is in its optimal performance. Selecting a vacuum breaker that meets your specific requirements will provide peace of mind. So that you can relax knowing that your plumbing system is in good hands.

Conclusion

Understanding how vacuum breakers work is pretty important. Vacuum breakers play a crucial role in preventing backflow and protecting the water supply. Understanding how they work is essential for maintaining safety and compliance in plumbing systems. By creating a barrier that stops contaminated water from flowing backward, vacuum breakers ensure the health and well-being of society.

by avi | Feb 12, 2024 | Tips

A pressure vacuum breaker prevents backflow contamination in water supply systems by creating a barrier of air. Water flows in one direction, and if a sudden pressure drop occurs, the air barrier prevents water from siphoning back into the supply.

When it comes to ensuring the house’s integrity and saving the system from water pressure. Pressure vacuum BRekaer is the first choice homeowners go for. With all the fuzz around a simple question comes to everyone’s mind what does a pressure vacuum breaker do?

In short, A pressure vacuum breaker prevents backflow contamination in water supply systems by creating a barrier of air. It makes sure the Water flows in one direction. But in time of sudden pressure drop the air barrier prevents water from siphoning back into the supply.

In this blog, we will discuss in-depth information about A PVB device and what it does for us. We will also explain why this single device is important for your house and family health. As well as simple installation and maintenance steps for longer utilization.

What Does A Pressure Vacuum Breaker Do

A pressure vacuum breaker is a device that protects against backflow. In the water system, it helps to prevent water system damage by preventing backward water pressure. It allows air to enter the system when there is a pressure drop. This prevents the inner system from creating a pressure vacuum. Which helps to prevent foul water from going into the mainstream.

A pressure vacuum breaker (PVB) is a crucial component in any irrigation system. It plays a vital role in keeping the water supply safe and free from contaminants. To better understand its function, let’s dive into the definition and purpose of a pressure vacuum breaker.

Definition

A pressure vacuum breaker is a backflow prevention device. which is installed on plumbing systems and outdoor irrigation systems. Its design helps to prevent the backflow of water from the irrigation system. Which prevents foul water from into the public water supply.

Purpose

The primary purpose of a pressure vacuum breaker is to protect it from contamination. It provides an effective barrier between the irrigation system and the drinking water system. Ensuring that there is no cross-contamination between the lines.

Once installed, the pressure vacuum breaker creates a break in the plumbing system. Allowing air to enter and create a vacuum. This vacuum prevents the water from flowing back into the water supply when the pressure in the system drops.

One of the key reasons for installing a pressure vacuum breaker is to comply with local plumbing codes. This device is essential to prevent water contamination and protect public health.

Pressure vacuum breakers are very common in outdoor irrigation systems. Where there is a higher risk of backflow because of fertilizers and different synthetic substances. At the point when these substances blend in with the water supply it causes extreme health hazards.

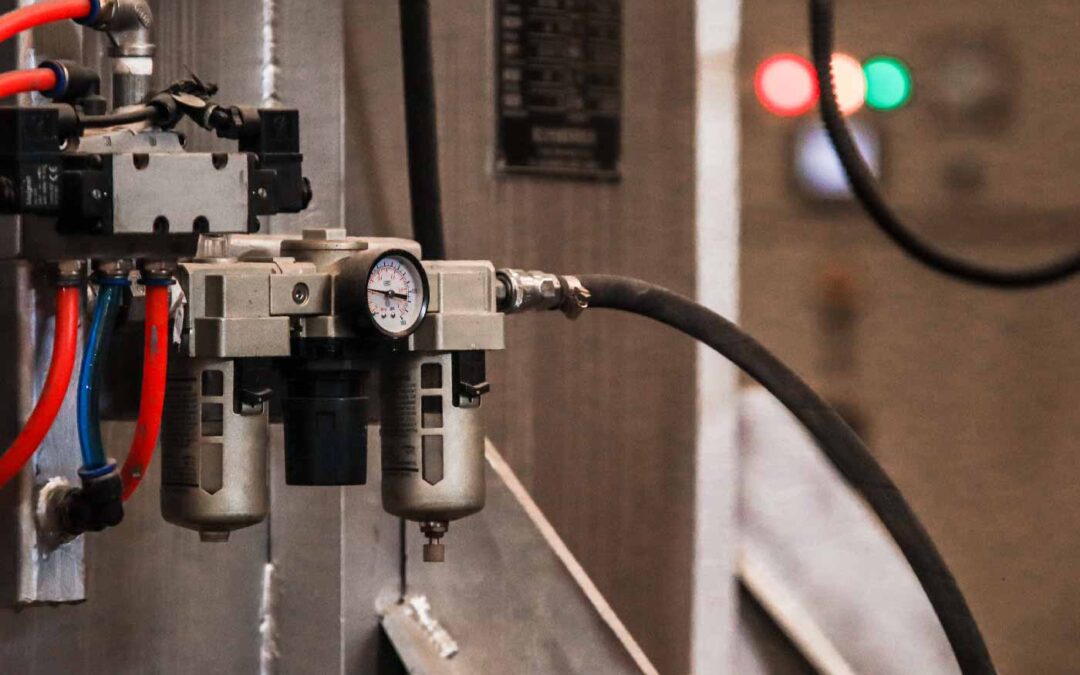

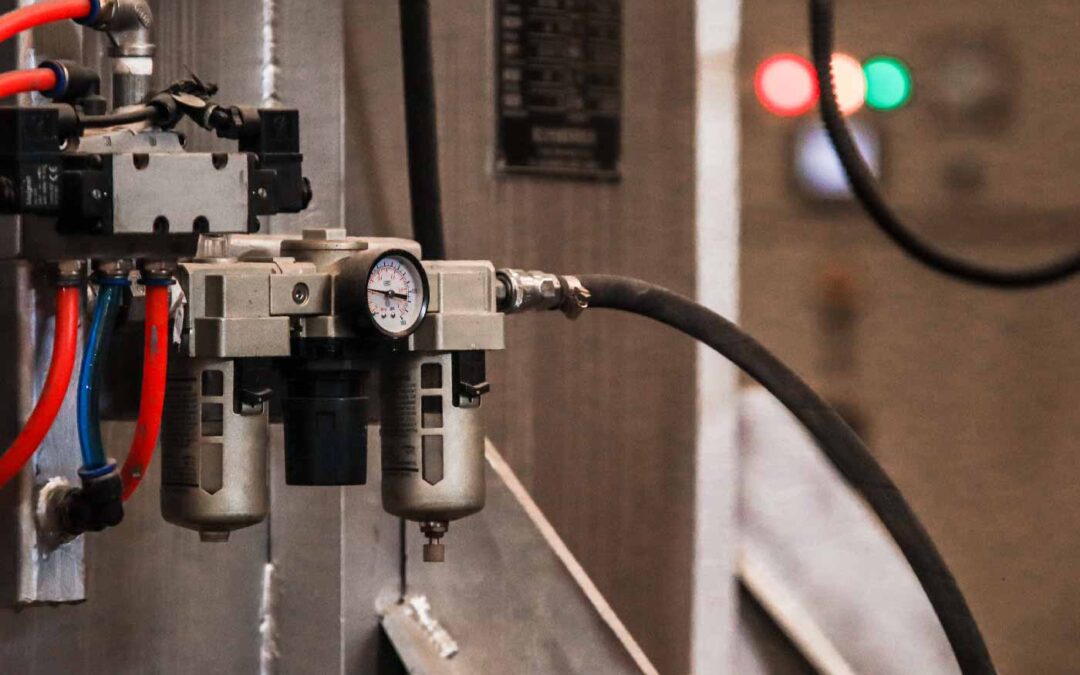

Components Of A Pressure Vacuum Breaker

A pressure vacuum breaker consists of various components that work together to prevent backflow and ensure the safety of the water supply. Its main purpose is to protect against cross-contamination by creating a barrier between the potable water supply and any potential pollutants or contaminants.

Inlet

The inlet is a crucial component of a pressure vacuum breaker (PVB). It is the point of entry for water into the device from the main water supply. The inlet is typically found at the bottom of the PVB. Where it has a connection to the main water line. This ensures a constant flow of water to the PVB and allows it to function effectively.

Air Inlet Valve

The air inlet valve is responsible for allowing air to enter the pressure vacuum breaker. It is located at the top of the device. When the design helps to prevent contaminants from entering the water system while allowing air to flow freely. This valve opens when the pressure in the system drops, which allows air to enter and prevent backflow.

Check Valve

The check valve is a vital component of the pressure vacuum breaker. It can be found between the inlet and the outlet and ensures that water flows in only one direction. This valve prevents backflow, which occurs when water flows back into the main water supply. The check valve ensures that the water can only flow out of the device to the desired location.

Outlet

The outlet is where the water exits from the pressure vacuum breaker. Then it flows to its certain location. It typically has a connection to the irrigation system of the whole house. The outlet lets the water to flow freely while preventing any backflow from occurring. It plays a crucial role in ensuring that the water is flowing properly. Also, ensure that it does not contaminate the main water supply.

How A Pressure Vacuum Breaker Works

A pressure vacuum breaker is an important part of a water irrigation system, designed to prevent the backflow of water into the main water supply. Wondering what does a pressure vacuum breaker do? Let’s dive into understanding how it works.

Normal Operation

During normal operation, water flows through the pressure vacuum breaker. Creating a vacuum within the system along the stream. This vacuum draws air in through the air inlet. Disrupting the flow of water in the event of a pressure loss. The air inlet is key to ensuring the pressure within the system remains in proper balance. This allows the device to function effectively.

Backflow Prevention

The primary function of a pressure vacuum breaker is to prevent backflow. Backflow occurs when water reverses in the backward direction. Which flows back into the main water supply. This can happen due to a drop in water pressure, potentially causing contamination of the drinking water. The pressure vacuum breaker creates a physical barrier. This prevents the backflow of water and safeguards the purity of the water.

Credit: www.irrigationrepair.com

Installation And Maintenance

Installation and maintenance are crucial aspects of understanding what a pressure vacuum breaker does. Proper installation ensures the optimal functioning of the pressure vacuum breaker. But regular inspections, cleaning, and repairs help maintain its efficiency. In this section, we will delve into the various aspects of installation and maintenance in detail.

Proper Installation

Proper installation of a pressure vacuum breaker is essential to ensure its effectiveness in preventing backflow. You can follow the steps for a successful installation:

- Begin by locating a suitable spot for the pressure vacuum breaker. It should be installed at least 12 inches above the highest point in the irrigation system.

- Once the location is final, connect the pressure vacuum breaker to the water supply line. Make sure the connections are secure and leak-free.

- Install isolation valves before and after the pressure vacuum breaker to allow for easy shut-off and maintenance.

- Ensure that all connections are tight and that there is no water leakage.

- Once everything is in place, test the pressure vacuum breaker to ensure it is functioning correctly. Refer to the manufacturer’s instructions for the testing procedure.

Proper installation of a pressure vacuum breaker not only safeguards the water supply but also ensures compliance with local regulations and guidelines related to backflow prevention.

Regular Inspections

Regular inspections are essential to identify any issues or potential problems. By conducting routine checks, you can proactively address any concerns before they escalate. Here are some key aspects to consider during inspections:

- Check for any signs of physical damage, such as cracks or corrosion, on the pressure vacuum breaker body.

- Inspect the valves and seals for any signs of wear or leakage. Replace any faulty components promptly.

- Verify that the air inlet vents are clear of debris. Clogged vents can hinder the proper functioning of the pressure vacuum breaker.

- Ensure that all valves and isolation devices are fully operational and do not show any signs of malfunction.

Regular inspections help maintain the integrity of the pressure vacuum breaker. Which also helps to prevent any potential backflow incidents that could jeopardize the water supply.

Cleaning And Repairs

Cleaning and repairs play an integral role in the maintenance of a pressure vacuum breaker. Regular cleaning helps remove debris and buildup that can impede its functioning. When it comes to cleaning and repairs, consider the following:

- Regularly clean the pressure vacuum breaker by carefully removing any accumulated dirt or grime.

- Inspect the check valves for any signs of damage or foreign objects that may obstruct proper flow. Clean or replace them as necessary.

- If any parts of the pressure vacuum breaker are damaged or malfunctioning, repair or replace them promptly to ensure continued efficiency.

Adhering to a regular cleaning and repair schedule enhances the longevity of the pressure vacuum breaker, keeping it in optimal condition for years to come.

Importance Of Pressure Vacuum Breakers

Pressure vacuum breakers play a crucial role in protecting water supply systems by preventing backflow contamination. They ensure that water flows in one direction, preventing contaminants from entering the water supply. Install and maintain pressure vacuum breakers for safe and clean water.

Protecting Against Backflow

A pressure vacuum breaker is a crucial component of any plumbing system. They work tirelessly to protect against the potential danger of backflow. Backflow is the reversal water flow of a plumbing system. Which has enough possibilities to contaminate clean water with harmful substances, chemicals, or pathogens.

By installing a pressure vacuum breaker, you can significantly minimize the risk of backflow occurrences. This device acts as a barrier, preventing water from flowing back into the main water supply. It works by creating a one-way valve that only allows water to flow in one direction. While the other ensures that contaminated water may not mix with the clean water supply.

Complying With Codes And Regulations

It is necessary to install a pressure vacuum breaker to maintain local codes and regulations. Many health departments and other governing facilities have shown the necessity to install a PVB. Because of the all-round safety and integrity of the water supply installing PVB is not essential.

Codes and regulations surrounding plumbing and water management are put in place to safeguard public health and maintain water quality standards. By following these restrictions and codes you can prevent water contamination and also from the diseases that prevail. Follow committee standards for water preservation regulations and save yourself from water contamination diseases.

In addition to complying with codes and regulations, installing a pressure vacuum breaker can also provide peace of mind. Knowing that your plumbing system is equipped with the necessary safety measures to prevent backflow can give you confidence that you and your family are drinking and using clean, uncontaminated water.

Conclusion

What does a pressure vacuum breaker does is a straightforward answer. Be it residential or commercial purposes A PVB system is essential. A pressure vacuum breaker is essential to protect the water supply from contamination. Understanding its functionality and role in maintaining safe water systems is crucial for homeowners and businesses. Proper maintenance and regular inspections are key to ensuring the effective operation of this device.

by avi | Feb 11, 2024 | Maintenance

When it comes to ensuring the house’s integrity and saving the system from water pressure. Pressure vacuum BRekaer is the first choice homeowners go for. With all the fuzz around What Is A Pressure Vacuum Breaker? PVB is a device that helps to prevent the contamination of drinking water from water backflow. By using a check valve and air inlet valve this device prevents the water pressure from creating a water vacuum. Maintaining minimal water pressure ensures the safety of the water supply alongside your family.

In this blog, we will discuss in-depth information about A PVB device. We will also explain why this single device is important for your house and family health. As well as simple installation and maintenance steps for longer utilization.

What Is A Pressure Vacuum Breaker

A pressure vacuum breaker is a device used to prevent backflow in plumbing systems. It works by creating a barrier that prevents water from flowing back into the main water supply. These devices are commonly used in irrigation systems and outdoor plumbing fixtures to protect against contamination.

A pressure vacuum breaker is commonly known as a vacuum breaker. It is a crucial component in plumbing systems that helps prevent backflow in water systems. Backflow occurs when the flow of water turns backward. Making contaminated water enter the clean water supply. This can lead to health hazards and contamination of the water supply.

How Does A Pressure Vacuum Breaker Work?

A pressure vacuum breaker operation is quiet and effective as well. It consists of two main parts: a check valve and an air inlet valve. The check valve permits water to flow in one direction while preventing it from flowing backward. The air inlet valve allows air to enter the system, creating a pressure vacuum. This vacuum helps to break the flow and prevents backflow.

When there is an increase in pressure within the plumbing system. Like pressure failure in the system or pump. The check valve closes, preventing water from flowing backward. Necessarily, the air inlet valve opens, allowing air to enter and create a backward pressure. This breaks the vacuum and stops the water from flowing in reverse. Which is why it’s so effective in preventing backflow.

The Importance Of Backflow Prevention

Protecting the Clean Water Supply

A pressure vacuum breaker plays a vital role in safeguarding the integrity of the water supply. Preventing the backward flow of contaminated water ensures that only clean, potable water reaches our taps, reducing the risk of waterborne diseases and health hazards.

Adherence to regulations

Plumbing codes requires the installation of pressure vacuum breakers. In order to comply with backflow prevention regulations and better agreements. By implementing this device, property owners and plumbers stay in compliance with local laws and regulations. While also avoiding potential fines and penalties.

Maintaining water quality

Backflow incidents can contaminate the stream water supply. Things like hazardous substances, chemicals, and bacteria can contaminate them. Pressure vacuum breakers act as a critical barrier. They prevent this contamination and maintain a high quality of our drinking water.

Preventing cross-connections

Cross-connections between potable and non-potable water sources can occur. In settings, like residential, commercial, and industrial spaces this is fairly common. Pressure vacuum breakers effectively prevent cross-connections. Eliminating the risk of cross-contamination and protecting the integrity of the clean water supply.

Cost-effective solution

Installing a pressure vacuum breaker is a cost-effective measurement. In comparison to other potential consequences of backflow incidents. By integrating this device into the plumbing system. Both homeowners and businesses can safeguard their health and investments.

As an essential component of any plumbing system, a pressure vacuum breaker ensures the safety and quality of our drinking water. By understanding how it works and acknowledging the importance of backflow prevention, we can take proactive measures to protect ourselves, our communities, and the environment from the dangers of contaminated water.

Common Applications For Pressure Vacuum Breakers

Residential Irrigation Systems

A pressure vacuum breaker (PVB) is commonly used in residential irrigation systems to protect against backflow contamination. To stop water from returning to the main water supply, a PVB is installed at the sprinkler system’s water outlet. This guarantees that the water utilized for the water system stays separate from the public water supply, defending against expected contaminations and synthetics that might be available in the water system framework.

Commercial Watering Systems

Pressure vacuum breakers are common in commercial settings. Places such as parks, sports fields, and golf courses, to maintain the water supply’s safety and integrity. These frameworks help to prevent water system reversal. This can happen anytime if there is a sudden drop in pressure in the water system. By creating a vacuum it prevents foul water from entering into the normal water supply.

Installation And Maintenance Of Pressure Vacuum Breakers

Pressure vacuum breakers are essential for the installation and maintenance of plumbing systems as they prevent the backflow of contaminants into the water supply. These devices create a vacuum to break the pressure and protect water quality.

Installing and maintaining a pressure vacuum breaker (PVB) is crucial for the proper functioning of your plumbing system. Understanding the proper installation guidelines and maintenance checklist can ensure the longevity and effectiveness of your PVB.

Proper Installation Guidelines

When it comes to installing a pressure vacuum breaker, it is essential to follow these guidelines to guarantee its correct operation:

Locate the ideal placement

Select an area with better ventilation. Position the PVB at least 12 inches above the highest point in your irrigation system. This elevation will ensure maximum performance for your system.

Protect from freezing

Install the PVB in an area that can protect your device from a freezing atmosphere. Proper insulation or heat tape can help when you are dealing with cold situations. In this way, you can also prevent damage by freezing conditions.

Consider local regulations

Familiarize yourself with the specific plumbing codes and regulations in your area. This ensures compliance and helps avoid potential issues down the line.

Secure connections

Use appropriate fittings to ensure leak-free connections. Tighten the nuts and bolts properly without overtightening, as this may lead to damage or leaks.

Keep it accessible

Make sure the PVB is easily accessible for future inspections, repairs, and maintenance. This accessibility will save you time and effort in the long run.

Maintenance Checklist Tips For Longevity

To ensure the longevity and functionality of your pressure vacuum breaker, it is necessary to conduct regular maintenance using the following checklist:

- Visual inspection: Regularly examine the PVB for signs of wear, leaks, or damage. Look for cracks, corrosion, or loose fittings, and address any issues immediately.

- Clean the vents: Inspect the air vents to ensure they are clear of debris or obstructions. Clear any blockages, using a brush or high compression of air blast.

- Check valve operation: Verify that the check valves are working correctly. They should open and close smoothly without any resistance. Replace any faulty valves promptly.

- Test the backflow preventer: Periodically test the backflow preventer to confirm its effectiveness. This can be done using a gauge or a professional testing kit. Consult the manufacturer’s instructions for the appropriate testing protocol.

- Flush the system: Regularly flush your irrigation system to remove any materials or debris that may accumulate over time. This preventive measure helps maintain optimal performance.

Remember, proper installation and ongoing maintenance are crucial for the efficient operation of your pressure vacuum breaker. Following certain guidelines and regular check-ups will ensure optimal conditions. By which you can ensure the safety of your drinking water and extend the life of your PVB.

Choosing The Right Pressure Vacuum Breaker For Your Needs

Now that you know What Is A Pressure Vacuum Breaker it’s time to pick the right PVB. For safety and reliability reasons a pressure vacuum breaker (PVB) plays a crucial role. But with so many options choosing the right PVB for your needs can be hard to figure out. It’s important to consider several factors, top brands in the market, and why houses require a PVB.

Factors To Consider

Before making a decision, it’s essential to keep a few key factors in mind:

- Water Pressure: Determine the water pressure in your area, as different pressure vacuum breakers are suitable for different water pressure levels.

- Application: Consider the proper use of the pressure vacuum breaker. Are you installing it for a residential property, commercial building, or irrigation system?

- Size and Space: Ensure that you choose a pressure vacuum breaker. If it fits the available space and meets the size requirements of your plumbing system.

- Price Range: Set a budget and explore options within that range. Keep in mind that quality and reliability should be the primary consideration. So while making a decision don’t look over price alone.

- Manufacturer Warranty: Check if the pressure vacuum breaker accompanies a manufacturer guarantee. In the event of any defects or malfunctions, this may offer assurance and protection.

Top Brands In The Market

Several reputable brands offer high-quality pressure vacuum breakers. The following are some of the top brands worth considering:

| Brand |

Features |

| Apollo Valves |

Known for their durable construction and reliable performance, Apollo Valves pressure vacuum breakers are a popular choice among professionals. |

| Watts |

With their extensive experience in the industry, Watts offers a range of pressure vacuum breakers with advanced features to ensure optimal protection against backflow. |

| Febco |

Febco pressure vacuum breakers are known for their easy installation and maintenance, making them a preferred choice for homeowners and DIY enthusiasts. |

| Wilkins |

Wilkins’s pressure vacuum breakers are designed to meet stringent industry standards, providing reliable backflow prevention for residential and commercial applications. |

Why Houses Require A PVB

By installing a PVB, you ensure that the water always flows in the right direction. Protecting your drinking water from potential pollutants and also your system from blocking up. This is especially important for houses with irrigation systems or other sources. Mostly for systems that could introduce non-potable water into the plumbing system.

Choose a pressure vacuum breaker that meets your specific needs. Make sure it provides reliable protection against backflow, ensuring the safety of your water supply. Don’t jump for any PVB when you’re facing a problem. Be more creative and accurate about it when it comes time to choose one.

Troubleshooting And Repairing Pressure Vacuum Breakers

A pressure vacuum breaker is a critical component of your irrigation system. They ensure the safety of your potable water supply. However, like any device, it can have issues that may require troubleshooting and repair. So it’s common to have ideas about the repair and maintenance of pressure vacuum breakers. This will enable optimal performance and better health integrity along with your house.

Identifying Common Issues

When it comes to identifying common issues there are a few key choices. Such as leaks, abnormal pressure with water flow, or an irregular discharge from the device. Additionally, visible signs of corrosion or damage to the components can be your root cause.

Steps To Fixing A Faulty Pressure Vacuum Breaker

It is essential to address any abnormalities with your pressure vacuum breaker. When attempting to fix or troubleshoot a broken pressure vacuum breaker, follow these steps:

- Inspect the device for any visible damage, leaks, or corrosion, focusing on the valve components and seals.

- Clean the pressure vacuum breaker to remove any debris or sediment that may be obstructing the proper flow of water.

- Test the device for proper functionality by conducting a system check. This will make sure that all components are operating as they are meant to.

- If necessary, replace any faulty or worn-out parts. This will restore the pressure vacuum breaker to its previous optimal working conditions.

Frequently Asked Questions

What Is A Pressure Vacuum Breaker?

A Pressure Vacuum Breaker (PVB) is a mechanical device used in plumbing systems to prevent the backflow of contaminated water into the main water supply.

How Does A Pressure Vacuum Breaker Work?

A Pressure Vacuum Breaker works by utilizing a check valve and an air inlet valve. It creates a barrier that keeps foul water from streaming into the main water stream. The air inlet valve opens when the water pressure drops. This allows the air to enter the system and prevents backflow.

Why Is A Pressure Vacuum Breaker Important?

A Pressure Vacuum Breaker is essential. Because it guarantees that the water in your pipe framework stays safe and contamination-free. It keeps you and your family safe through the prevention of harmful substances.

Conclusion

To safeguard drinking water supplies from contamination, a pressure vacuum breaker is an essential component. Understanding its capability and support is fundamental for guaranteeing the security and honesty of our water frameworks. We can maintain the health and well-being of our communities by adhering to the appropriate installation and maintenance guidelines.

by avi | Feb 9, 2024 | plumbing Services

Backflow preventer leakage is like a nightmare to homeowners. Because this poses threats to health as well as the integrity of the whole house. So, when you have a backflow problem you are generally dealing with twice the suffering. On this, it’s better to know how to stop a backflow preventer from leaking.

To prevent backflow leakage first check for any cracks or loose fittings and repair or replace them accordingly. Additionally, ensure that all valves are fully shut off and properly sealed.

Regularly inspect and clean the backflow preventer to prevent any debris or buildup that could lead to leaks. Here in this article, we will explain how to stop a backflow preventer from leaking effectively. Which will ensure the proper maintenance and better integrity of your plumbing system.

Causes Of Backflow Preventer Leakage

Leakage from a backflow preventer is a common problem for many homeowners. Several causes can contribute to this problem. Seals that are worn out are one of the main causes. The backflow preventer’s seals may deteriorate over time, causing leaks.

Another potential reason is high water pressure. High pressure can put a stain. Which results in leaking as a result of excessive water pressure. Inadequate installation is another possibility. Normally, the backflow preventer will not work accordingly with improper installation. Which could lead to leakage.

To forestall reverse preventer spillage, it is essential to examine and supplant broken-down seals consistently. Leak prevention requires pressure control and monitoring. It is essential to recruit an expert who is knowledgeable about introducing discharge preventers accurately to guarantee that the framework is working appropriately. Homeowners can avoid the hassle and potential damage of a leaking backflow preventer by taking these preventative measures.

Signs Of Backflow Preventer Leakage

Backflow preventers play a crucial role in maintaining the integrity of a plumbing system. It’s important to be aware of the signs of backflow preventer leakage. This will help to address the problem promptly also with ease.

One indication is visible water leakage around the backflow preventer. This can manifest as dripping or pooling water near the device. Another sign is reduced water pressure throughout the plumbing system. If you notice a decrease in water flow, it could be due to a leaking backflow preventer.

Additionally, a potential consequence of a leaking backflow preventer is water contamination. If the device fails to prevent the reverse flow of water. It leads to water contamination through mixing with substances while posing health risks.

To prevent backflow preventer leakage, regular inspections and maintenance are crucial. But for a better solution to the leakage problem, It’s a recommendation to hire an expert. They will explore and address any issues promptly as well as provide solutions for better results.

Steps To On how to stop a backflow preventer from leaking

Inspect and Replace Seals

Make sure the backflow preventer’s seals are intact and in good condition with regular inspection. To stop backflow in drains, immediately replace the seals if they show any signs of wear.

Install a Pressure Regulator

Installing a pressure regulator can help regulate the water pressure in the system, preventing excessive pressure that can lead to a backflow preventer leaking.

Properly Adjust the Pressure

The backflow preventer’s pressure settings must have proper adjustments to stay within the perfect range. This will forestall reverse in channels and limit the gamble of a spilling discharge preventer.

Check Valve Seals

Inspect the check valves in the backflow preventer to ensure they are sealing correctly. Adjust or replace them as needed to maintain proper functionality.

Check and Correct Installation Issues

Consistently investigate the establishment of the reverse preventer to distinguish any issues that could add to spillage. If you want to keep a backflow preventer from leaking, it’s important to fix problems with the installation right away.

Maintenance Practices For Backflow Preventers

Regular inspections, cleaning, and lubrication are crucial maintenance practices. Proper maintenance of these devices ensures their efficient functioning. Ultimately helping to minimize the risk of backflow in drains.

Inspecting the backflow preventer regularly allows for early detection of damages. During inspections, look for visible leaks, cracks, or worn-out parts. They are likely to cause the preventer to leak.

Cleaning the preventer removes any debris or sediment. Which accumulates over time and affects its performance. Lubricating the moving parts helps to maintain their smooth operation and prevents friction-induced leaks.

In addition to regular inspections, it is essential to conduct annual testing and certification to verify the preventer’s effectiveness and compliance with regulations. If you can do this practice properly it can greatly contribute to preventing a leaking backflow preventer. While ensuring the overall safety of the drainage system.

When To Seek Professional Help

Complex Repairs

If you are done with the basics but there is no success. Well, then it’s time you go up to call in a professional. Complex repairs require professional knowledge and tools that an expert plumber can provide. Their diagonalization is accurate and without any issues. They will admit the necessary repair your system will require for better performance. Their expertise will ensure the job is done correctly and prevent further damage to your plumbing system.

Legal Compliance Issues

Fixing a leaking backflow preventer is not only crucial for the proper functioning of your drainage system but also for legal compliance. Backflow preventers are required by law in many areas and must be maintained in good working condition. If you are unable to resolve the leakage issue on your own, it is advisable to seek professional help to avoid potential legal consequences.

Conclusion

So learning how to stop a backflow preventer from leaking is a knowledge all should know about. Preventing a backflow preventer from leaking is essential for maintaining a healthy water system. By following the steps you can effectively troubleshoot and resolve issues with your backflow preventer. Which will ensure a reliable and efficient performance. Taking proactive measures to address leaks will ultimately contribute to the overall safety and functionality of your plumbing system.

by avi | Feb 8, 2024 | Repair Drain pipe

Backflow in drains causes major headaches and expensive damage to your home. It occurs when water from the main sewer line flows back into your main water stream. Which leads to flooding or contamination. Backflow issues in plumbing can be a significant concern for homeowners, as they compromise the integrity of your water supply. To prevent this from happening, it is essential to take proactive measures and install suitable backflow prevention devices.

We will explore effective methods on How to Prevent Backflow in Drains. We will explore the terms to ensure the safety and integrity of your plumbing system. By following these preventive measures, you can avoid costly repairs and maintain the proper functioning of your drains. Let’s dive into the solutions that will safeguard your home from backflow risks.

What Is Backflow In Drains

Backflow is a common plumbing issue that, if not handled properly, can result in significant issues. It happens when a drainage system’s flow turns around, allowing contaminated water to enter clean water sources. The best way to stop backflow is to know what causes it.

Backflow: what is it? Reverse in plumbing implies an adjustment of water strain inside the waste framework. This could be brought on by a number of things, like a burst pipe, a blockage downstream, or a drop in the pressure of the water.

Causes of backflow

One of the main causes of backflow is a sudden drop in water pressure. This can occur when there is a high demand for water in a particular area or when a water main breaks. resulting in the water returning in the opposite direction. Back siphonage, which occurs when the plumbing system experiences negative pressure, is another cause. This indicates that the system’s pressure is higher than the water supply’s. resulting in the return of water to the supply line. Moreover, bringing about a block or obstruction of a channel. eventually leading to backflow.

For the drainage system’s integrity and the safety of clean water sources, preventing backflow is essential. Backflow prevention in drains can be effectively prevented by performing routine maintenance and inspections on plumbing systems, installing backflow prevention devices, and disposing of waste appropriately

How To Prevent Backflow In Drains

To prevent backflow in drains, one effective method is installing check valves. Check valves are devices that allow water to flow in one direction and prevent it from flowing back. By installing check valves at key points in your plumbing system, you can ensure that water or sewage does not back up into your house.

A popular type of check valve used for backflow prevention is the Reduced Pressure Principle Backflow Preventer (RPBP). This device’s sole purpose is to protect against backflow in plumbing systems. It maintains a higher pressure in the system than in the water supply so the water does not flow backward.

In addition to checking valves, there are other backflow prevention devices available. Devices such as atmospheric vacuum breakers and double-check valve assemblies. These devices stay at specific points in your plumbing system. And helps you to prevent backflow and protect your house from potential sewage backup.

With regards to forestalling discharge in channels, taking into account the particular requirements of your pipes system is significant. The best way to prevent backflow and avoid potential issues like sewage backup in your home can be determined by consulting a plumber.

Install an Air Gap

One effective method to prevent backflow is by installing an air gap. This non-mechanical solution creates a physical space between the water outlet and the flood level of a fixture. Commonly found in kitchen faucets, air gaps allow water to flow out normally. While preventing any backflow, safeguarding your water from potential contaminants.

Consider a Reduced Pressure Principle Backflow Preventer (RPBP)

Most common for commercial uses, but RPBP can be a viable solution for residential plumbing. This device features valves that automatically close due to water pressure response. When there is a drop in water pressure, the valve closes. The close valve then traps the water until the flow or pressure becomes sufficient enough. In this way RPBP effectively prevents backflow. Though less prevalent at home, the RPBP offers a robust preventive measure.

Explore Barometric Loops

Barometric loops can be a difficult installation for your plumbing system. But provides a straightforward solution to backflow prevention. These U-shaped piping arrangements create a barrier that makes it difficult for water to travel upward, reducing the risk of backflow.

Invest in Pressure Type Vacuum Breakers

Vacuum breakers offer direct installation to your existing plumbing system. Vacuum breakers can track the system pressure serving as a continuous monitor for the system. When these devices detect a pressure drop. A check valve promptly closes, preventing backflow and maintaining the integrity of your water supply.

Hose Bib Backflow Preventers for Outdoor Fixtures

Backflow can affect outdoor faucets, especially those that are connected to hoses. Introducing a hose tucker reverse preventer is a reduced at this point compelling arrangement. This device ensures that water only flows in one direction and quickly releases any backflowing water in the event of a pressure drop.

Importance Of Preventing Backflow

Preventing backflow in channels is urgent to keep away from potential well-being perils and harm to the pipes framework. Backflow in plumbing can seriously harm human health by contaminating clean water with harmful substances.

Backflow can likewise make harm the pipe’s foundation, prompting exorbitant fixes and burdens. It is essential to ensure that the drainage system has proper design and installation. With the appropriate backflow prevention devices in place, to prevent backflow in the drains.

Normal upkeep and review are likewise significant in recognizing and resolving any potential issues that could prompt discharge. By understanding how to prevent backflow in drains and going to proactive lengths, landowners can shield the well-being and uprightness of their pipe frameworks.

Frequently Asked Questions

Q: What causes backflow in drains?

A: Backflow can happen in channels when there is an adjustment of pressure. Making the foul water stream in reverse.

Q: What are the root causes of drain backflow?

A: Backflow in channels can happen because of blockage in pipes, high water pressure, plumbing framework breakdowns, or erroneous establishment of really look at valves.

Q: How Might I Forestall Discharge In Channels?

A: It is essential to regularly maintain your plumbing system. Installing check valves, and making certain adjustments is helpful. This will ensure appropriate drainage and venting systems are in place to prevent backflow in drains.

Conclusion

It is essential to address backflow issues and understand terms of How to Prevent Backflow in Drains to keep your water supply safe and clean. Whether through direct arrangements like air holes or more modern gadgets. Like pressure-type vacuum breakers, air gap RPBP. These arrangements guarantee the dependable and smooth activity of your pipes. If backflow issues persist, consulting an expert plumber will assist in customizing preventative measures. They will offer better solutions depending on your house’s specifications. Which will keep your water clean, your pipes inconvenience-free, and your home a sanctuary of well-being and security.